euroTECH supports agricultural machinery manufacturer CLAAS with vacuum lifting technology

Infos & Download

Characters including spaces: 5,791, reprint permitted, 2 images

Contact

Monika Schuster

Phone: +49 7428 93912 – 0

email: presse@etvac.de

Download Press Release

& Pictures

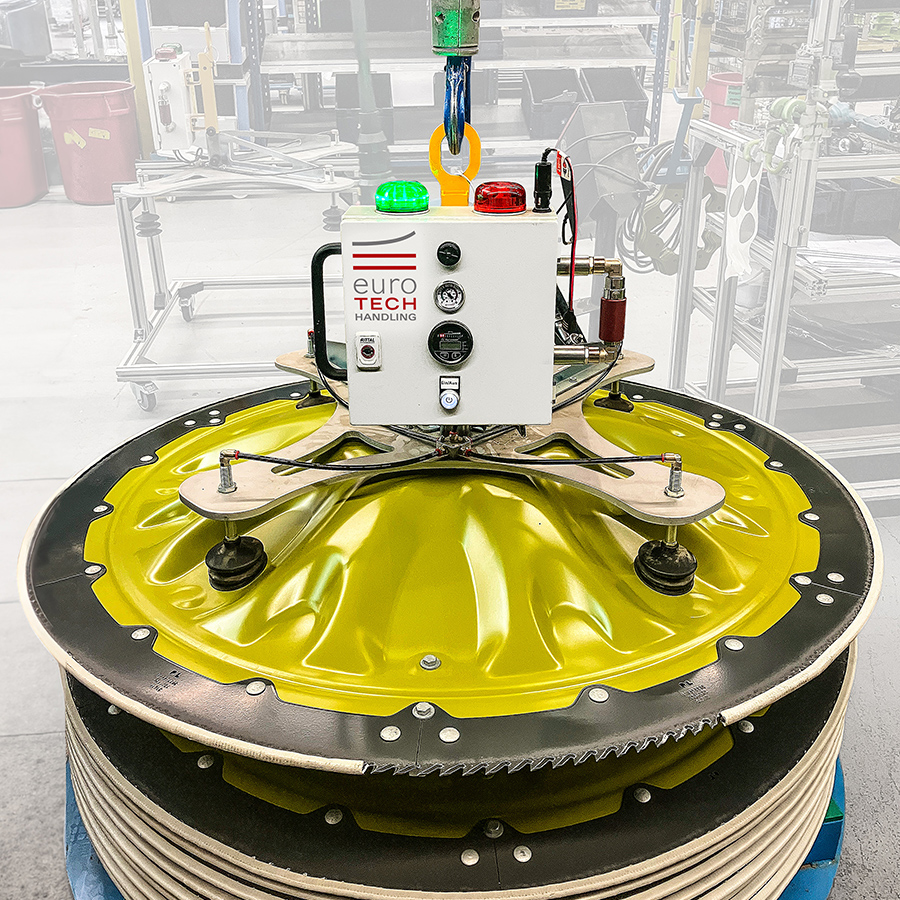

In the production of agricultural vehicles, a lot of emphasis is placed on individual configurations and superstructures. People are often required to carry out assembly work here. To make the handling of large or sharp-edged parts safer and more ergonomic, the CLAAS company uses vacuum lifting technology from euroTECH. The Rosenfeld specialists adapted the lifting devices from the extensive standard range exactly to CLAAS’ needs.

The agricultural machinery manufacturer CLAAS manufactures, tests and develops machines for forage harvesting and attachments for the JAGUAR forage harvester in Bad Saulgau. The chopping unit – the heart of the JAGUAR – is also manufactured in this production facility. Alongside state-of-the-art production facilities, the site has one of the most modern test centres for forage harvesting technology in the world. For maize harvesting, the JAGUAR is equipped with the ORBIS attachment. This highly successful product series consists of circular knife segments that rotate under plate-shaped sheet metal housings with a diameter of about one metre. Arranged side by side and folded out, they achieve working widths of 4.50 m to 9 m.

Suitable vacuum technology sought

In the past, the large and sharp-edged elements had to be moved by hand. Besides the physical strain, there was always a certain safety risk in directly handling the sharp knife edges. Although these are usually fitted with a guard, injuries cannot be ruled out. Christian Schmidt, head of assembly at CLAAS, remembers the challenge: “We had the problem of having to mount assembled discs with sharp knives on the devices. It was clear to us that vacuum technology might be suitable here. But we couldn’t figure out how to design such a device to fit our requirements in terms of functionality and economic efficiency.”

Vacuum full service at euroTECH

CLAAS came to the vacuum specialists at euroTECH via a recommendation. The special feature of euroTECH is that you can choose from a range of standard devices that can then be customised. This is made possible thanks to our own engineering team – whose members know all the ins and outs about vacuum technology. In addition, euroTECH has its own production of vacuum components that can be replaced individually. All in all, this perfect combination of standard, customisation and accessories creates extremely economical and functional vacuum solutions that optimally meet customers’ needs.

Targeted adaptation

The area sales manager of euroTECH, Mirko Weinhold, recommended the eT-Hover-modesty vacuum lifting device to CLAAS. This device enables both horizontal and vertical handling and can be turned manually or pneumatically. It is operated entirely with compressed air. With a carrying capacity of up to 250 kg, the device has sufficient reserves. Assembly manager Christian Schmidt describes the cooperation: “Based on the standard, the vacuum lifting device was adapted to us. The way we can discuss ideas and exchange information with euroTECH is simply excellent. After several variants were suggested to us, we tried these out until we’d worked out the right solution together. Although the ultimate solution was bespoke to us, everything remained within the planned financial framework. For us, the vacuum solution we found from euroTECH means a considerable gain for the occupational safety and health of our employees.”

Easy and safe handling

The eT-Hover-modesty is attached to an overhead crane at CLAAS. This picks up the curved round plates horizontally from a storage rack and transports them to a work table for knife assembly. First the loose discs without knives are lifted onto the device, followed by the knives for fastening. Finally, the entire construction unit is placed on a transport rack with the same eT-Hover-modesty to be mounted to the machine – again with the help of the euroTECH vacuum lifting device. All eT-Hover units are operated with a clear ergonomically designed control unit that is intuitive to use.

Several vacuum solutions in use

Six eT-Hover models are now in use as assembly aids for the CLAAS ORBIS front attachments. Some of them have also been modified for sheet handling. Complementing this, vacuum lifting devices with bellow suction cups have been supplied that can accommodate round pressure rollers the size of a fire extinguisher. Another device from the eT-Hover series used at CLAAS is the eT-Hover-allround. This device lifts parts weighing up to 500 kg and is versatile as a multi-talent and “all-rounder”.

euroTECH vacuum solutions ideal for agricultural technology

This wide range of applications and the high degree of flexibility in adapting to customer requirements make euroTECH an ideal partner for agricultural technology. For another well-known agricultural machinery manufacturer, euroTECH supplies vacuum solutions that bring bonnets to the vehicle at exactly the right angle for assembly. This was implemented with the eT-Hover-univac line, which is ideal for inserting metal sheets, roof superstructures or windscreens. In addition, euroTECH offers specially developed MTC protective covers for the suction cups, which leave virtually no marks on the elements to be lifted. These diverse properties also make the eT-Hover-univac line interesting for agricultural machinery workshops – thanks to its efficient and ergonomic function as a self-sufficient module operating independently of external compressed air or energy supply. Farmers are often unaware of the numerous potential applications of vacuum technology – or such applications simply seem too complicated. With euroTECH, it is easy to find new ways to move loads intelligently.